Packaging label thermal printers and mechanisms

Efficient, high-performance printing solutions for labeling in packaging lines

In the packaging industry, the accuracy and durability of printed labels are essential for identifying, tracking, and ensuring compliance with industry regulations.

Packaging label printers integrated into production lines play a crucial role in providing clear and precise labels that contain important product information, such as barcodes, batch numbers, expiration dates, and more.

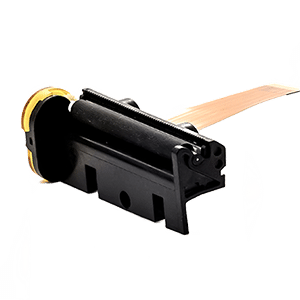

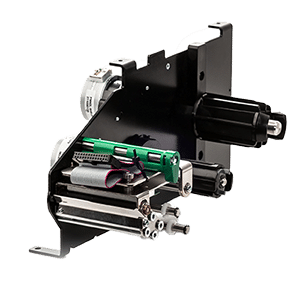

APS thermal printers and mechanisms are engineered to deliver fast, high-quality label printing in high-volume environments, ensuring efficient operations and compliance across packaging lines in manufacturing, logistics, and other sectors.

Explore our thermal printer range

Why choose APS for your packaging label printers ?

APS thermal printers and mechanisms are designed to meet the demanding needs of packaging lines, providing reliable, high-speed label printing that ensures accuracy and efficiency in labeling processes. Here is why APS is the best choice for your packaging label printer needs :

High-speed, efficient printinG

APS thermal printers and mechanisms are built for fast, accurate label printing, ensuring that every label is printed in real time to keep up with the speed of automated packaging lines. This helps maintain the flow of operations without creating delays or bottlenecks.

Superior print quality and precision

APS printers and mechanisms deliver high-resolution labels that ensure every barcode, batch number, and product description is clearly readable and scannable. This level of precision is essential for inventory management, product tracking, and regulatory compliance.

Adaptability for various label types

APS thermal printers and mechanisms are compatible with a wide range of media, including standard labels, specialized packaging tags, and even linerless labels. This flexibility ensures that the printer can handle diverse labeling needs in the packaging sector.

Built for tough environments

Packaging lines often operate in challenging conditions, such as high humidity, dust, or fluctuating temperatures. APS thermal printers and mechanisms are designed to withstand these conditions, delivering consistent, high-quality printing in industrial environments.

Custom solutions for packaging lines

APS offers customized printing solutions to match the specific requirements of your packaging lines. Whether you need custom label sizes, unique printing formats, or special materials, APS provides tailored solutions that fit your operational needs.

Looking for the perfect thermal printer and mechanism for your packaging label needs ?

APS offers customized printing solutions designed for the packaging industry, providing fast, durable, and accurate labeling for all your packaging processes.

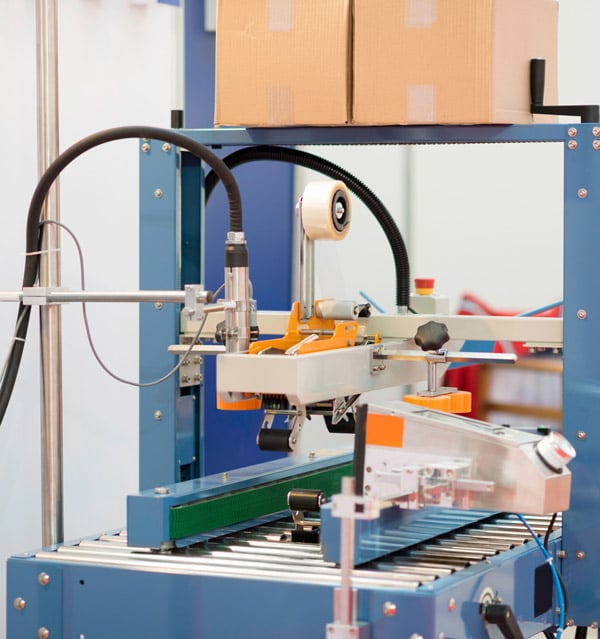

The importance of thermal printers for packaging labels

In packaging lines, thermal printers are used to produce labels that not only identify products but also provide essential information for tracking and inventory management. These labels must be printed accurately and quickly to keep up with high-speed production environments, where any delay could lead to bottlenecks and inefficiencies.

Thermal printers are preferred in packaging environments due to their ability to produce crisp, durable labels that remain legible under various conditions, including frequent handling and exposure to moisture or temperature changes. With no ink or toner required, thermal printing also reduces maintenance needs and ensures consistent, uninterrupted printing, making it an ideal choice for busy packaging lines.

Additionally, using high-quality thermal paper or labels ensures that barcodes, text, and other critical information are printed clearly and remain scannable throughout the product’s lifecycle, from production to distribution.

Key factors to consider when selecting a thermal printer or a mechanism for packaging labels

When selecting a thermal printer or a mechanism for packaging labels, it is important to consider factors that ensure reliability, performance, and ease of use. Here are some key factors to keep in mind :

- Media flexibility for various packaging needs

Packaging lines often require labels in different sizes and formats, depending on the product. Choose a thermal printer or a mechanism that can handle a variety of label media, including standard adhesive labels, linerless labels, and specialized packaging materials, to meet your product labeling needs.

- Print speed and efficiency

In high-speed packaging environments, printing labels quickly is essential to avoid production delays. Choose a printer or a mechanism that offers high-speed printing without compromising print quality, ensuring that every label is issued in real time to keep operations running smoothly.

- Durability in industrial environments

Packaging lines operate in tough conditions, where printers may be exposed to moisture, dust, and frequent vibrations. Choose a thermal printer or a mechanism designed for long-term durability, ensuring reliable performance in even the harshest environments.

- Energy efficiency

Continuous labeling operations can drive up energy costs. Select a low-energy thermal printer or mechanism to reduce operational costs while maintaining high performance in high-demand packaging environments. This helps ensure that your labeling process is both efficient and cost-effective.

- Ease of integration with packaging systems

Packaging systems vary widely, and it’s important to choose a thermal printer that can be easily integrated with your existing production line software and hardware. APS thermal printers and mechanisms are designed for easy system integration, ensuring seamless communication between your labeling process and packaging line.

Upgrade your packaging label printing system with APS thermal printers and mechanisms

APS delivers fast, reliable, and efficient printing solutions for packaging lines, ensuring smooth operation and superior label quality across your production process.