Thermal printers 101: the thermal printhead, the core of thermal printing

The thermal printhead is the most crucial component of a thermal printer. It determines print quality, durability, and overall performance. Understanding how it works and how to maintain it properly can significantly improve your printing results and extend the lifespan of your device.

Welcome to “Thermal Printers 101”, a series designed to provide a comprehensive understanding of thermal printing technology. Whether you’re selecting a new thermal printer, troubleshooting an issue, or optimizing performance, this series covers everything you need to know.

In this article, we focus on the thermal printhead, the essential component that makes direct thermal printing possible. We’ll explain how it works, what affects its performance, and how to ensure optimal print quality and longevity.

What is a thermal printhead?

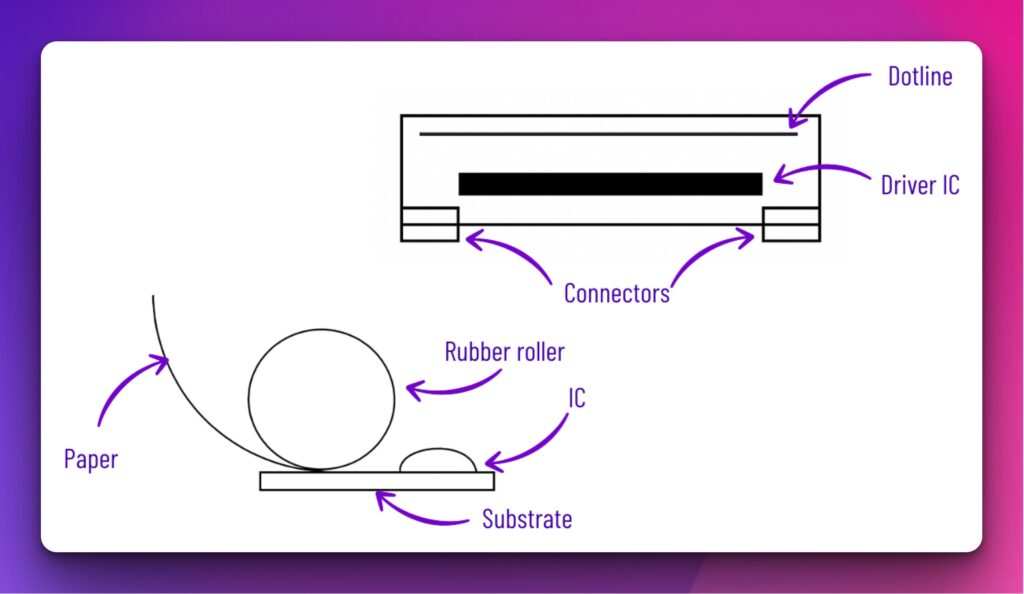

The thermal printhead is a precision-engineered component responsible for transferring heat to the thermal paper in direct thermal printing. It consists of tiny resistive heating elements (dots) arranged in a row. Each element heats up selectively, creating text, barcodes, or images on the specially coated paper.

The printhead’s resolution, typically measured in dots per inch (dpi), determines the clarity of the print. Standard resolutions include 203 dpi (8 dots/mm) and 300 dpi (12 dots/mm), with higher resolutions available for specialized applications.

How does a thermal printhead work?

- Electrical signals activate the heating elements. The printhead receives digital data, and specific heating elements are activated according to the desired print pattern.

- The elements heat up instantly. Each tiny resistor in the printhead generates heat in milliseconds.

- The heat reacts with the thermal paper. The paper’s heat-sensitive coating darkens where heat is applied, forming the printed image.

- The printhead continuously moves with the paper. The printer’s motion system ensures the paper advances at a controlled speed, creating a smooth and precise print.

Factors affecting printhead performance

A thermal printhead’s efficiency and lifespan depend on several factors. Understanding these variables can help extend the life of your printhead and maintain consistent print quality.

1. Print speed and energy control

Higher print speeds generate more heat, which can affect printhead longevity. Advanced printers adjust energy output dynamically to ensure consistent, high-quality prints at varying speeds.

2. Paper quality

Low-quality thermal paper can contain abrasive particles, increasing wear on the printhead. Using high-grade thermal paper reduces friction and extends the life of the printhead.

3. Maintenance and cleaning

Dirt, dust, and residue from thermal paper can accumulate on the printhead, causing streaks, poor print quality, or even permanent damage. Regular cleaning with approved cleaning wipes or alcohol swabs helps maintain performance.

4. Printhead pressure and alignment

Uneven pressure between the printhead and platen roller can lead to inconsistent printing or premature wear. Ensuring proper alignment and even pressure distribution optimizes print quality.

Common thermal printhead issues and solutions

Even the best printheads require maintenance. Here are some common problems and how to fix them.

1. Faded or uneven prints

- Cause: Low power settings, dirty printhead, or poor-quality paper.

- Solution: Increase print density settings, clean the printhead, and use high-quality thermal paper.

2. Printhead streaking

- Cause: Debris buildup on the printhead surface.

- Solution: Clean the printhead regularly using manufacturer-recommended cleaning materials.

3. Partial or missing lines in prints

- Cause: Burnt-out heating elements.

- Solution: If cleaning does not resolve the issue, the printhead may need replacement.

4. Printhead overheating

- Cause: High print speeds with excessive energy output.

- Solution: Reduce printing speed or adjust energy settings to prevent excessive heat buildup.

What impacts the lifespan of a thermal printhead?

A thermal printhead is the most critical and expensive component of a thermal printer, and its longevity directly affects printing costs and efficiency. While printheads are designed to last millions of print cycles, their lifespan depends on several key factors:

1. Heat management and energy efficiency

Thermal printheads generate heat to produce an image, but excessive heat can prematurely degrade the resistive elements. Advanced energy management in modern printers adjusts power levels dynamically, ensuring:

- Consistent print quality without overheating.

- Extended printhead life by reducing thermal stress.

- Lower power consumption, making printers more energy efficient.

2. Print speed and friction

High-speed printing generates more friction between the printhead and the thermal paper. Over time, this friction can wear down the protective layer of the printhead, leading to reduced print quality and permanent streaking. To minimize this:

- Manufacturers optimize the coating materials on printheads.

- Regular cleaning removes dust and particles that increase friction.

- Using the right paper thickness and smoothness helps reduce wear.

3. Paper quality and debris buildup

The type of thermal paper used has a major impact on printhead longevity. Low-quality paper contains abrasive fillers that gradually wear down the printhead surface. Best practices include:

- Choosing high-quality thermal paper with low debris content.

- Regularly cleaning the printhead to remove dust and buildup.

- Ensuring correct paper alignment to avoid uneven pressure on the printhead.

4. Environmental factors

Thermal printheads are sensitive to their operating environment. Exposure to:

- Dust and dirt can clog heating elements.

- Extreme temperatures can cause uneven heating and wear.

- Moisture and humidity may affect thermal paper reaction and print clarity.

Proper printer placement, maintenance, and regular inspections help ensure optimal printhead performance and longevity.

By understanding these factors, businesses can significantly extend the life of their thermal printers, reduce downtime, and lower maintenance costs.

How to extend the lifespan of your thermal printhead?

Replacing a printhead can be costly, so prolonging its lifespan is essential for reducing operational costs. Here are the best practices to maintain printhead longevity:

- Use high-quality thermal paper. Avoid low-grade paper that can wear down the printhead.

- Optimize print settings. Use the lowest possible energy setting that still produces clear, high-contrast prints.

- Handle with care. Avoid touching the printhead surface, as oils and dust can degrade performance.

- Ensure proper printer alignment. Misalignment can cause uneven wear and affect print quality.

Why the thermal printhead is critical to printing quality

The printhead is responsible for 90% of the final print quality in a thermal printer. A well-maintained printhead ensures:

- Sharp, legible text

- Consistently high-resolution images

- Accurate barcode printing for scanning

- Minimal downtime due to maintenance issues

Choosing a thermal printer with a high-quality printhead ensures durability and consistent performance, reducing the total cost of ownership.

Why choose APS for high-performance direct thermal printing?

APS specializes in high-quality direct thermal printing solutions, integrating long-lasting, high-precision printheads for optimal print quality and efficiency. Our thermal printers are engineered for:

- Superior durability, with printheads rated for up to 100 km of printed material.

- Energy-efficient operation, reducing wear and extending lifespan.

- Easy maintenance, with accessible components for quick cleaning.

Whether you need a compact mobile printer or a high-speed industrial printer, APS offers the most reliable, cost-effective thermal printing solutions for your business.

Browse our thermal printer range