Reliable, High-Volume Label Printing for Pharmacy Automation Systems

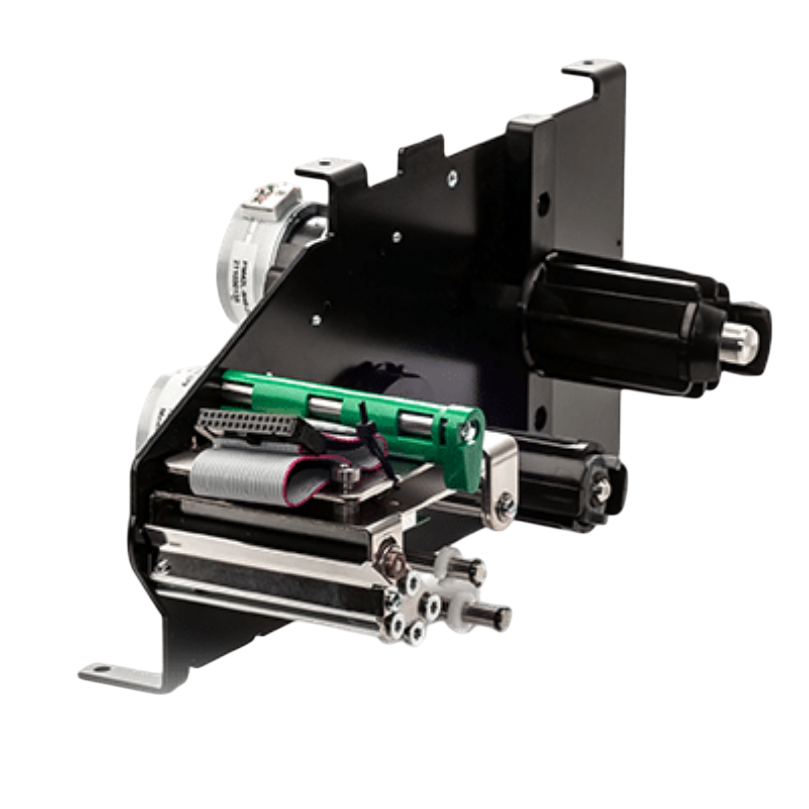

APS supplied the LPM2300 heavy-duty label printer, engineered for industrial-grade performance and long life operation within automated pharmacy systems.

THE CHALLENGE

Parata Systems required a high-performance, heavy-duty label printing solution for its Parata Max® pharmacy automation platform, designed to support high-speed, high-volume prescription fulfillment. The printer needed to reliably produce accurate prescription labels containing patient information, medication details, dosage instructions, barcodes, and regulatory data—at speeds matching Parata Max’s automated output. The solution also had to support continuous-duty operation, withstand extended production cycles, and maintain print precision and consistency in central fill and high-throughput pharmacy environments.

THE SOLUTION

APS supplied the LPM2300 heavy-duty label printer. The solution was validated under sustained, high throughput duty cycles to confirm thermal stability, mechanical durability, and consistent print quality, including barcode readability and label precision required for downstream verification and pharmacy compliance workflows.

THE RESULT

APS and Parata engineering teams collaborated closely to ensure the APS LPM2300 could be integrated seamlessly into the Parata Max® automation architecture. The integration addressed mechanical mounting, service access, and tolerance requirements to support high-speed label handling, while aligning electrically with Parata’s system power and EMC design constraints. Control and communication interfaces were implemented to enable deterministic, event-driven label generation synchronized with real-time prescription and dispensing operations.

THE BESPOKE THERMAL PRINTER

By integrating the APS LPM2300 heavy-duty label printer into the Parata Max® high-speed automation system, Parata delivers greater throughput, labeling reliability, and operational confidence —enabling pharmacies to scale fulfillment operations while maintaining accuracy, compliance, and patient safety.

KEY FEATURES OF THE SOLUTION

- Streamlined High-Volume Pharmacy Workflows: Integrated, high-speed labeling eliminates delays associated with external printers, maximizing throughput across automated dispensing lines.

- Reduced Risk of Labeling Errors: Automated printing directly from pharmacy systems minimizes manual intervention, supporting accurate patient-specific labeling.

- Heavy-Duty, Long-Life Performance: The APS LPM2300 is engineered for extended duty cycles, ensuring reliable operation during peak prescription volumes.

- Barcode-Ready Prescription Labels: Printed labels support barcode verification workflows, enabling downstream scanning, verification, and closed-loop medication processes.

- Support for Pharmacy Compliance: Accurate, standardized label output supports compliance with pharmacy regulations and medication labeling requirements.

- Improved Patient Safety: Fast, precise, and consistent labeling helps ensure the right medication reaches the right patient with the correct instructions, every time.

Let’s partner with us to create your bespoke thermal printer solution

Let APS design a custom thermal printing solution that meets your unique needs.

Request a quote today and see how APS can enhance your device with precision and reliability.