Thermal printers 101: key components of a thermal printer

A thermal printer is more than just a printhead and paper. It consists of several key components that work together to ensure precise, reliable printing. Understanding how these components function is essential for selecting the right printer and optimizing its performance.

Welcome back to “Thermal Printers 101”, a series dedicated to exploring the fundamentals of thermal printing technology. Whether you’re looking to gain a deeper understanding of how thermal printers work or need insights to select the right solution for your business, this series provides a comprehensive look at every aspect of the technology.

In this article, we’ll break down the three essential components of a thermal printer—the printhead, the motion system, and the sensors. Each plays a critical role in delivering high-quality, efficient, and reliable printing.

The thermal printhead: the heart of the printer

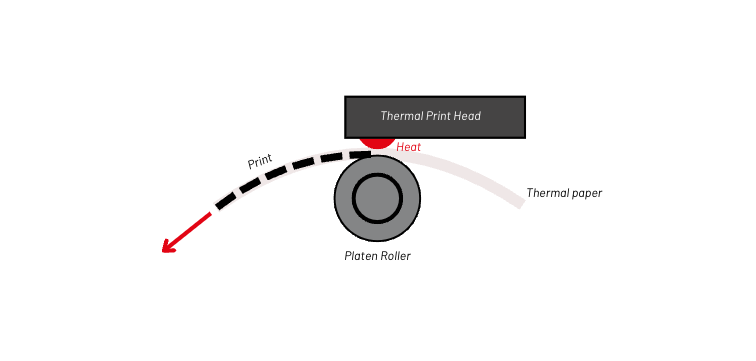

The thermal printhead is the most important component of a thermal printer. It is responsible for applying heat to the thermal paper, creating images by activating heat-sensitive coatings or transferring ink from a ribbon (in thermal transfer printing). The printhead contains a row of tiny heating elements (dots) that selectively heat up to form text, images, and barcodes.

How the printhead works

The printhead consists of:

- Resistor dots that heat up in response to electrical signals

- A protective glass or ceramic coating to prevent wear

- Integrated driver circuits that control heating intensity and timing

When power is applied to specific dots, they heat up and activate the thermal paper’s coating, producing an image. The number of dots per millimeter determines the resolution of the print. Common resolutions are 203 dpi (8 dots per mm) and 300 dpi (12 dots per mm).

Factors that impact printhead performance

- Print speed: Higher speeds require efficient heat dissipation to maintain quality.

- Energy control: Consistent power distribution prevents overheating and premature wear.

- Paper quality: Low-quality paper can cause excessive debris buildup, reducing printhead lifespan.

Since the printhead is the most sensitive and costly part of the printer, proper maintenance is crucial. Cleaning the printhead regularly extends its lifespan and ensures consistent print quality.

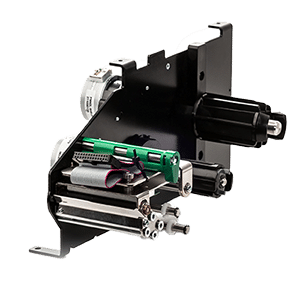

The motion system: ensuring precise paper movement

A thermal printer requires precise control over paper movement to align the printhead’s heating elements with the correct sections of the paper. The motion system consists of a stepper motor and a platen roller, working together to advance the paper at a controlled rate.

How the motion system works

- The stepper motor drives the paper forward in precise increments. Unlike traditional motors, stepper motors operate in small steps, ensuring accurate positioning of each printed line.

- The platen roller, a rubberized cylinder, presses the paper against the printhead, ensuring even contact and preventing paper slippage.

Key advantages of stepper motors in thermal printing

- Precise control: Stepper motors allow for high-accuracy paper movement, crucial for barcode printing and high-resolution images.

- Variable speeds: The motor speed can be adjusted based on printing requirements, optimizing energy use.

- Durability: Stepper motors have a long lifespan and require minimal maintenance.

Challenges in motion control

- Paper jams: Improper paper loading or debris can cause the paper to get stuck.

- Slippage: A worn-out platen roller can lead to print misalignment.

- Speed fluctuations: Inconsistent motor control can affect print consistency, especially for barcodes.

A well-designed motion system ensures smooth, accurate printing, preventing errors that could compromise readability and print quality.

Sensors: improving efficiency and reliability

Thermal printers incorporate multiple sensors to monitor key functions and ensure seamless operation. These sensors detect conditions such as paper presence, printhead position, and overheating, preventing errors and improving reliability.

Types of sensors in thermal printers

- Paper detection sensor

- Detects whether paper is loaded in the printer.

- Prevents the printhead from overheating by ensuring it doesn’t print on an empty roller.

- Typically an infrared or mechanical sensor.

- Printhead position sensor (head-up sensor)

- Detects whether the printhead is properly closed and in contact with the paper.

- Prevents printing when the printhead is lifted, avoiding paper misfeeds and print inconsistencies.

- End-of-paper sensor

- Signals when the paper roll is running out, preventing incomplete prints.

- Can be based on reflective optical detection for accurate readings.

- Temperature sensor (thermistor)

- Monitors the temperature of the printhead to prevent overheating.

- Adjusts energy output dynamically to maintain optimal print quality.

How sensors improve performance

- Reduces downtime by preventing paper jams and incomplete prints.

- Extends printhead lifespan by preventing unnecessary heating.

- Enhances user experience by automating error detection and minimizing manual intervention.

How the three components work together

For a thermal printer to function correctly, the printhead, motion system, and sensors must operate in perfect synchronization:

- The printhead generates heat patterns to create the printed image.

- The motion system advances the paper at a controlled rate to maintain alignment.

- The sensors monitor the process, detecting errors and optimizing performance.

Each component plays a crucial role in ensuring precise, high-speed, and reliable printing. A well-designed thermal printer optimizes the interaction between these elements to reduce downtime, enhance durability, and deliver high-quality prints consistently.

Why choose APS for direct thermal printing?

APS specializes in advanced direct thermal printing solutions designed with high-quality printheads, precise motion systems, and intelligent sensors. Our thermal printers are engineered for maximum reliability and efficiency, making them ideal for point-of-sale systems, kiosk applications, logistics, and medical labeling.

With a commitment to innovation and durability, APS provides compact and cost-effective thermal printing mechanisms that deliver fast, high-resolution prints with minimal maintenance. Whether you need a mobile printing solution or an industrial-grade printer, APS has the expertise to support your business.

Browse our thermal printer range

If you’re ready to embrace the future of thermal printing ? APS is here to help !

Contact APS today to learn more about our range of advanced thermal printers and how we can tailor solutions to meet the unique needs of your business.